Pallet Racking System Is Ideal for Pharmaceuticals. Learn How.

Best Educational Insituitions for Children in Medavakkam

January 6, 2022

Role of Logistics in a Healthcare Industry

April 2, 2022The pharmaceutical industry produces healthcare products and other items to improve our overall health. Temperature and humidity impact pharmaceutical products. Pharmaceutical supplies must be stored, retrieved, and shipped with extreme caution. Call the pallet and slotted angle racks manufacturers in Delhi (https://www.donracks.co.in/delhi/slotted-angle-racks/) to gain an insight on how to install a storage system in your facility. Keep reading to know more about the significance of steel racks in a pharmaceutical manufacturing unit.

Role of Pallet Racking System in Pharmaceuticals

Pharmaceutical manufacturing necessitates sophisticated warehousing operations that boost efficiency. Pallet racking is used in various applications in the pharmaceutical industry to support warehousing functions. It is used to store delicate products with controlled storage features at an affordable rate.

Pallet Racking solutions are used in pharmaceutical supply management to maximize available space and simplify pharmaceutical product movement. When storing products in this industry, the basic requirements are hygiene, temperature, and traceability. The pharmaceutical warehouse design must include a designated area for stock segregation to meet this requirement.

The layout of a pharmaceutical warehouse should be adaptable enough to accommodate seasonal changes in drug storage. Automated storage and retrieval must enable products to be moved out of the warehouse before expiration. Doing so will boost efficiency and precision. In pharmaceutical warehouses, certain storage systems are preferred over others to achieve the goals listed above.

Selective Pallet Racking (SPR) uses the entire warehouse height for storage. Thus, it is the most popular storage system in pharmaceutical warehouses. At the same time, a very Narrow Aisle Pallet Rack is used to maximize storage space.

Steel Racks Vs. Plastic Racks in Pharmaceutical Manufacturing

Pharmaceutical manufacturing frequently employs steel or plastic baskets and trays. Stainless steel alloys consistently outperform plastic polymers under all circumstances.

Stainless Steel Storage Solution

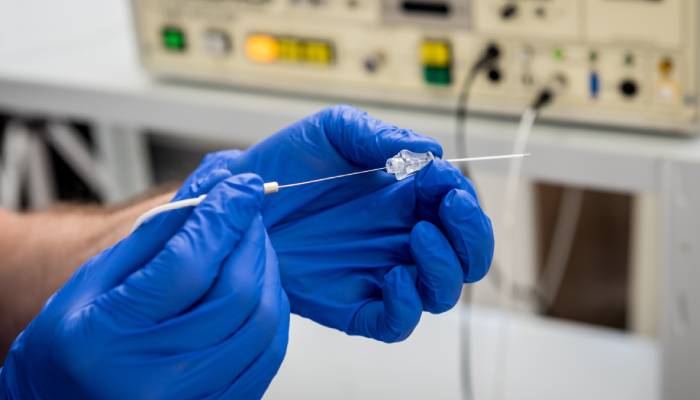

The stainless steel storage solution has been used in pharmaceutical companies for many years. Steel alloys can be coated with chemicals-resistant polymers to protect them from deterioration. Polymers have an advantage over harder materials like steel when working with mechanically brittle parts. These racks transport medicine containers, test tubes, and other parts from one filling, cleaning, and sanitation process to the next.

Steel baskets can be coated with softer polymers to reduce the likelihood of an impact, but the lifetime cost of ownership increases. Stainless steel is a broad category that encompasses tens of thousands of different steel formulations. Surgical steel is a type of stainless steel that is resistant to corrosion, available in various shapes and applications.

Plastic Storage Solution

A rack or basket made of inexpensive plastic is less expensive per unit than a comparable basket made of steel or stainless-steel wires. When heated to temperatures above 300°F, plastic baskets lose their shape and would deteriorate more quickly.

End-note

The pharmaceutical industry is growing at an incredible rate of 9-10% per year. Thus, pharmaceutical storage solutions must follow GMP guidelines and provide clear visibility of the products. If you intend to install a storage system for your warehouse or manufacturing facility, try investing in slotted angle racks Chennai.